Good practices should be applied in the whole range of productive activity, such as :

1. Environment of the production and production sites

Should be suitable for the storage and handling of grapes and / or wines. In particular, it must be free from any source of contamination.

2. In the vineyard

Respect of the good agricultural practices makes it possible to limit the risks related to the residues of plant protection products (marketing authorization, training of operators, maintenance of the equipment), ochratoxin A (restriction of parasite pressure) and ethyl carbamate (nitrogen inputs).

3. Transport of grapes to the production area

The transporting equipment (tractors, agricultural vehicles, trucks, trolleys) and the equipment in contact with the grapes (hand-harvesting or mechanical-harvesting, special benches with mobile carpet, destemmer, lift, screening strip, pumps, press) must be maintained and properly cleaned. The recommendations are the same as for processing equipment.

4. Wine making equipment and wooden barrels

All the equipment, transport pipes, tanks (of different materials), pumps, filters, barrels, bottling line must maintained in a high hygienic level in order to prevent microbiological, physical and chemical contamination of the wine.

In now days wine’s contamination of several microorganisms such as Brettanomyces is widely spread and affects the quality of wines. At the same time it is essential the use of cleansing products approved for the winemaking industry.

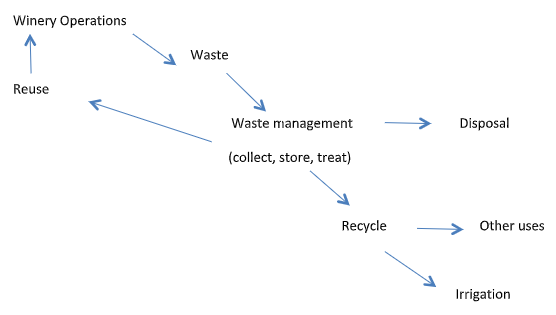

4. Waste management

Waste must be disposed of in accordance with current regulations

5. Design and arrangement

The design of the premises must facilitate the production process, ensure the safety of the operators and allow a good conservation of the dry materials, in particular those having the capacity to absorb certain smelly or toxic molecules (bentonite, corks, filtration, cartons, etc). Thus, a reasoned conception should take into account the ergonomics and the management of the flows will have to integrate and facilitate hygiene operations.

Of course, improvements can be made in the direction of better hygiene, for the already existing production sites. A plan of the premises can identify the different areas and points to check during periodic checks and can also be used to justify the application of good practices.

The layout of the premises must allow delimiting spaces dedicated to the different activities.

In any case, there must be separate premises, and prohibit even temporary storage, in premises that do not have the same functions.

The importance of a suitable environment and the maintenance of premises

a) General case

Natural materials: (clay floors, rock walls, etc.) are a traditional practice in the premises of production and storage of wine.

Temperature: crucial to avoid significant temperature differences. High temperatures are often detrimental to product quality and may have an indirect impact on the stability of products, e.g. difficulty maintaining SO2, development of native flora.

Lighting: good lighting makes it easier to assess the cleanliness of rooms and equipment. For storage rooms for bottles, prefer sodium lamps or diodes electroluminescent (LED) to avoid the taste of light (appearances of compounds sulfur volatiles linked to the exposure of wine to light) on white wines, especially those in bottles in white glass. Premises used for foodstuffs must have natural and / or artificial lighting.

Ventilation: The regulations require good ventilation of the premises, for preserving, among others, the workers’ health. During winemaking, ventilation is crucial for the safety of the personnel. Ventilation must be sufficient to remove excess moisture and avoid condensation to limit the proliferation of undesirable molds. The maintenance and cleaning of ventilation systems is also important.

b) Special specifications for wine-making and bottling rooms

The winemaking and bottling rooms are places dedicated to the food production and packaging. In this context, they must comply with the regulatory requirements specific to this type of facilities.

Walls and ceilings

a) floor coverings must be well maintained, easy to clean and, where necessary, disinfect.

(b) wall surfaces must be well maintained, without humidity, easy to wash and, if necessary, disinfect.

(c) ceilings, false and other suspended equipment shall be constructed in order to prevent fouling and to reduce condensation, the appearance of unwanted mold and the spillage of particles »

Openings

Avoid drafts, insects, dust, vectors of contaminations overtures

Foreign bodies

If necessary, secure glass and hard plastic parts to prevent the introduction of debris.

c) Mobile bottling

The requirements for this type of bottling, are referring to the CETIE Guide (International Technical Center for Custom Bottling and conditioning).

6. Clothes, sanitary

• Provide adequate locker rooms for company staff.

• Provide lavatories with washbasins at the exit and keep them clean; prefer a drying hand by hand towel.

• Ensure good ventilation of these places to the outside. These premises must not overlook the premises of elaboration.

• Recall the hygiene instructions of the staff by posting inside the premises.

• A sufficient number of toilets equipped with flush toilets and connected to an evacuation system effective must be available. Toilets must not lead directly to rooms used for the handling of foodstuffs.

• A sufficient number of well-located sinks for hand washing must be available.

• Washbasins for hand washing must be equipped with hot and cold running water and equipment for cleaning and for hygienic drying of hands. […]. Sanitary facilities must have adequate ventilation, natural or mechanical. ”

7. Raw materials

• Viti-vinicultural raw materials

Good management of viti-vinicultural raw materials makes it possible to limit the risks inherent in agricultural practices when the producer is different from the grower. It also limits the risk inherent to oenological practices when several producers intervene.